Apr. 19, 2023

If the capacitor is used improperly or is affected by other external factors during use, it will malfunction or be damaged. Especially for ceramic capacitors, the problem of ceramic capacitor leakage often plagues many engineers.

First of all, the surface insulation of the ceramic capacitor is reduced due to surface dirt. This kind of leakage current is not very large, generally in the microampere level, and the insulation value will increase when the hot air blows. Secondly, internal cracks, cracks caused by welding, and poor manufacturing of ceramic capacitors will also cause leakage. The leakage current caused by such cracks will continue to increase, and in severe cases, it will cause local fires. Many company technicians cannot analyze whether it is a capacitor failure. Because once soldering iron or heating, it will return to normal, many engineers often misanalyze the solder paste problem, many people do not analyze correctly the first time, and when analyzing accurately the second time, sample cutting microscope observation, it turns out tat it is indeed a capacitor problem. From a reliability standpoint, ceramic capacitor leakage is a typical low-stress failure, including monolithic capacitors, relays, and polyester capacitors. If the power supply is not clean, it will leak after working for a period of time under the abnormal DC voltage, and it will become more and more serious as time goes by.

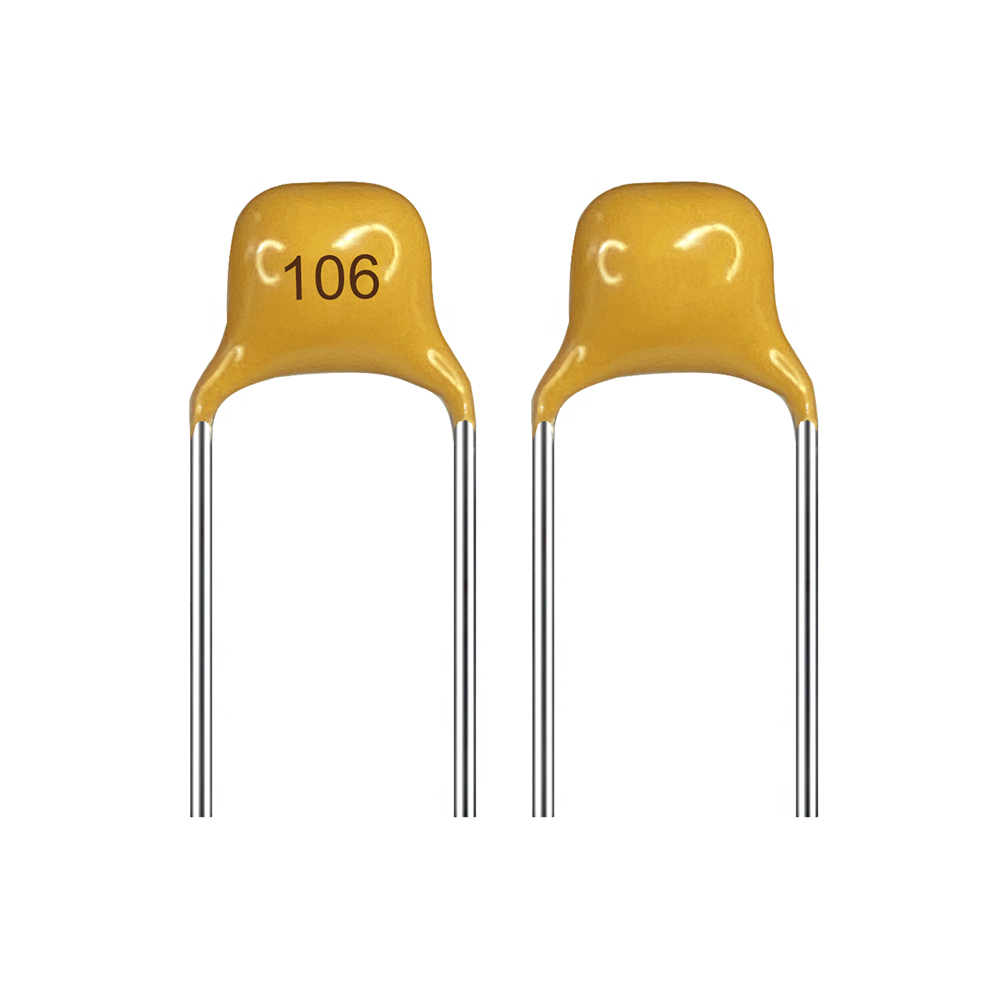

A ceramic capacitor is a capacitor that uses a ceramic material as the dielectric, with a metal film coated on the ceramic surface, and then sintered into an electrode at a high temperature. It is usually used as a loop of a highly stable oscillation circuit. In the process of shorting a ceramic capacitor, what caused the short circuit?

A short circuit is when the power supply is connected directly to a closed circuit through a wire, without a load. Short-circuit current refers to the current when it is not connected, which is equivalent to the current when a wire is directly connected to the positive and negative phases of the battery. The reasons for the short circuit of ceramic capacitors are as follows:

1) The quality is not up to standard.

2) High voltage breakdown.

3) The voltage is unstable.

4) Insufficient reserve margin.

5) The ambient temperature exceeds the range of use.

7)The ceramic capacitor is damaged during transportation.

Select a reliable manufacturer when purchasing electronic components can avoid a lot of unnecessary trouble. JYH HSU(JEC) Electronics Ltd (or Dongguan Zhixu Electronic Co., Ltd.) is an electronic components manufacturer whose factories are ISO 9000 and ISO 14000 certified.

Processes Used Producing Ceramic Capacitors

Apr. 19, 2023

Insignificant Electronic Component: MLCC

Apr. 19, 2023

+86 181 2299 5593

+86 18122995593

+86 769 8831 3605

Beside Luchong Bridge, Hou Road, Caibai Village, Daojiao Town, Dongguan, Guangdong, China

Navigation